OUR MANUFACTURING SERVICES

CAPABILITIES

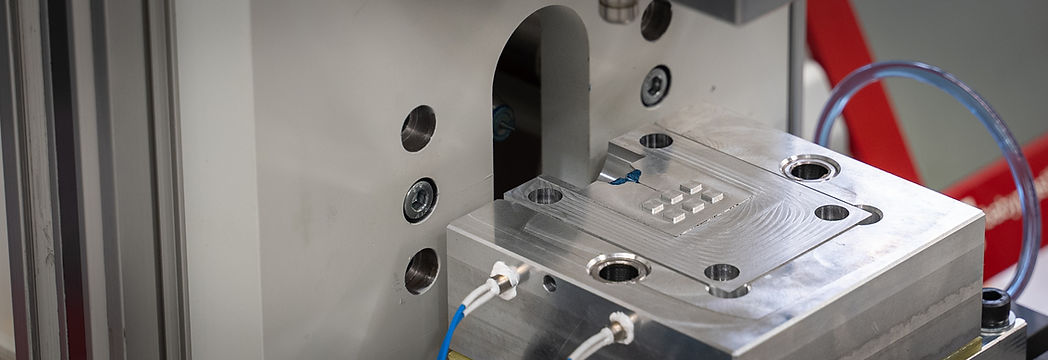

CNC Machining

-

Prototyping

-

High-Precision Components

-

Durable and Functional Parts

-

Custom Tooling, Jigs and Fixtures

-

Housings for Electronics and Mechanical Systems

-

Moulds for Casting and Injection Moulding

-

High-Speed Small Batch Production

-

3D Surface Machining

-

Replacement Parts for Equipment Maintenance and Repairs

PCB Assembly

-

Prototyping

-

Custom PCBs and Circuit Assemblies

-

Precision Electronic Components

-

Durable Enclosures and Casings

-

Custom Test Fixtures and Jigs

-

High-frequency RF and Signal Testing

-

Embedded Systems Integration

-

Environmental and Stress Testing

-

Replacement PCBs for Legacy Systems

-

Battery Management and Power Optimisation

-

IoT and Wireless Connectivity Solutions

-

High-speed Data Acquisition Systems

3D Printing

-

Prototyping

-

Form, Fit and Function Testing

-

Mould Prototyping for Casting

-

Custom Tool, Jigs and Fixtures

-

Assembly Testing

LSR Injection Moulding

-

Prototyping and Functional Testing

-

Seals and Gaskets

-

Shock Absorbing and Vibration Dampening Components

-

Electrical Insulation and Protection

-

Medical Device Components

-

High-Temperature and Chemical-Resistant Parts

-

Waterproof and Dustproof Enclosures

-

Custom Overmoulding